The global agricultural technology (Ag-Tech) sector is at an inflection point. As the world population grows and demands for sustainable, efficient, and ethical food production intensify, traditional farming methods are proving inadequate. The livestock industry, in particular, faces mounting pressures from labor shortages, environmental regulations, and volatile market conditions. This confluence of challenges presents a massive opportunity for disruptive, scalable solutions. Trackfarm, an AI-powered smart livestock solution, is not just optimizing existing farm operations—it is fundamentally redefining the economics of swine production, making it a compelling investment for forward-thinking capital.

I. The Investment Thesis: Why Smart Livestock is the Next Big Bet

The market for smart farming is projected to reach tens of billions of dollars in the coming years, with livestock management being a primary growth driver. Investors are increasingly seeking technologies that offer a clear return on investment (ROI) by addressing core industry pain points. Trackfarm’s value proposition is built on three pillars: radical efficiency gains, de-risked operations, and unparalleled scalability.

A. The Crisis of Traditional Swine Farming

Traditional swine farming is characterized by high labor dependency, reactive management, and significant operational variability.

- Labor Intensity: The need for constant, skilled human oversight for monitoring animal health, growth, and environmental conditions is a major cost and bottleneck.

- Inconsistent Outcomes: Manual monitoring leads to delayed detection of diseases, suboptimal feeding, and inconsistent growth rates, resulting in high mortality and extended fattening periods.

- Environmental Volatility: Poorly managed barn environments (temperature, humidity, gas levels) directly impact animal health and feed conversion ratios, eroding profit margins.

Trackfarm directly addresses these inefficiencies by replacing human labor with precision AI and automated hardware, transforming the farm from a labor-intensive operation into a data-driven manufacturing process.

II. Trackfarm’s Dual-Engine Disruption: AI Software and Automated Hardware

Trackfarm’s solution is a powerful synergy of proprietary software and robust hardware, designed to create a fully optimized, self-regulating farm environment.

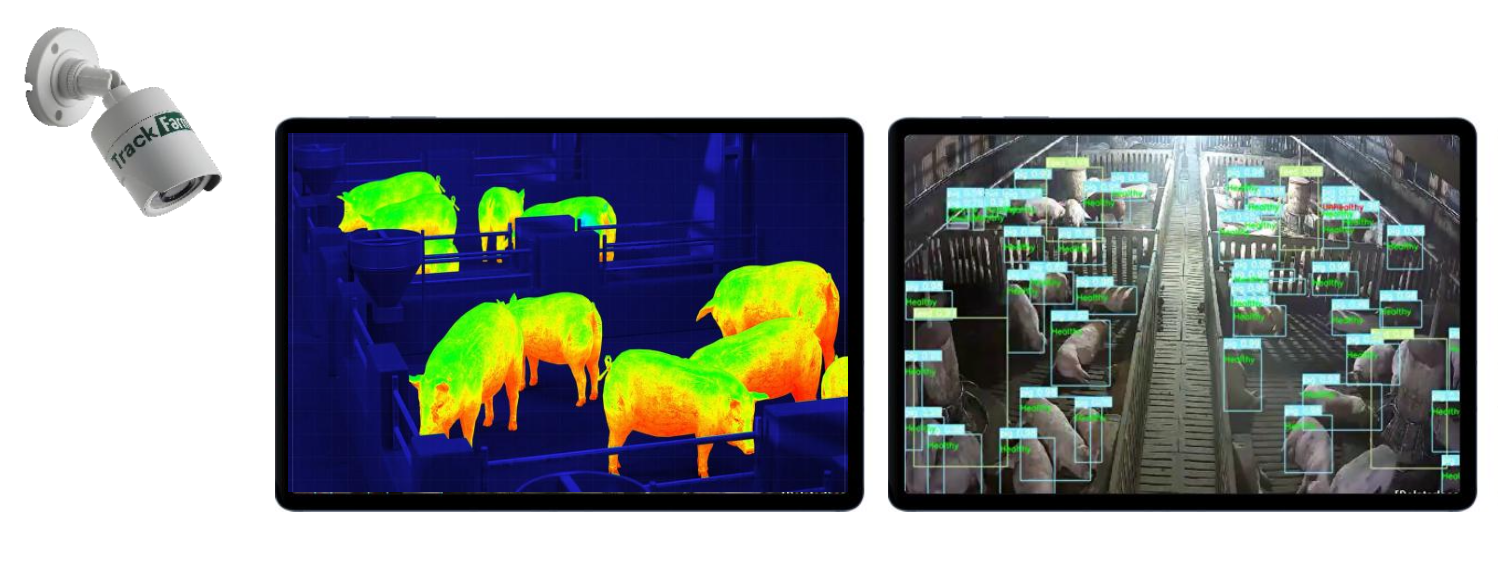

A. The AI Monitoring Engine (Software)

The core of Trackfarm is its AI-driven monitoring system, which leverages advanced computer vision and data mining to achieve a level of precision and labor reduction previously unimaginable.

| Feature | Traditional Method | Trackfarm AI Monitoring | Investment Impact |

|---|---|---|---|

| Labor Requirement | High (Constant human oversight) | Minimal (AI replaces 99% of human monitoring tasks) | Reduced OPEX, Scalability |

| Growth Analysis | Manual weighing, visual estimation | Automated, real-time growth analysis and individual tracking | Optimized Feed Conversion, Higher Yield |

| Slaughter Prediction | Experience-based, subjective timing | AI-driven prediction of optimal slaughter time | Maximized Profit Margin per Head |

| Disease Detection | Reactive (Visual symptoms, often too late) | Proactive (Behavioral and environmental anomaly detection) | Reduced Mortality Rate, De-risked Assets |

The system’s ability to manage pig populations, analyze growth, and predict optimal market timing is a game-changer. By minimizing human intervention, it eliminates human error and maximizes management efficiency, allowing a single manager to oversee over 3,000 animals.

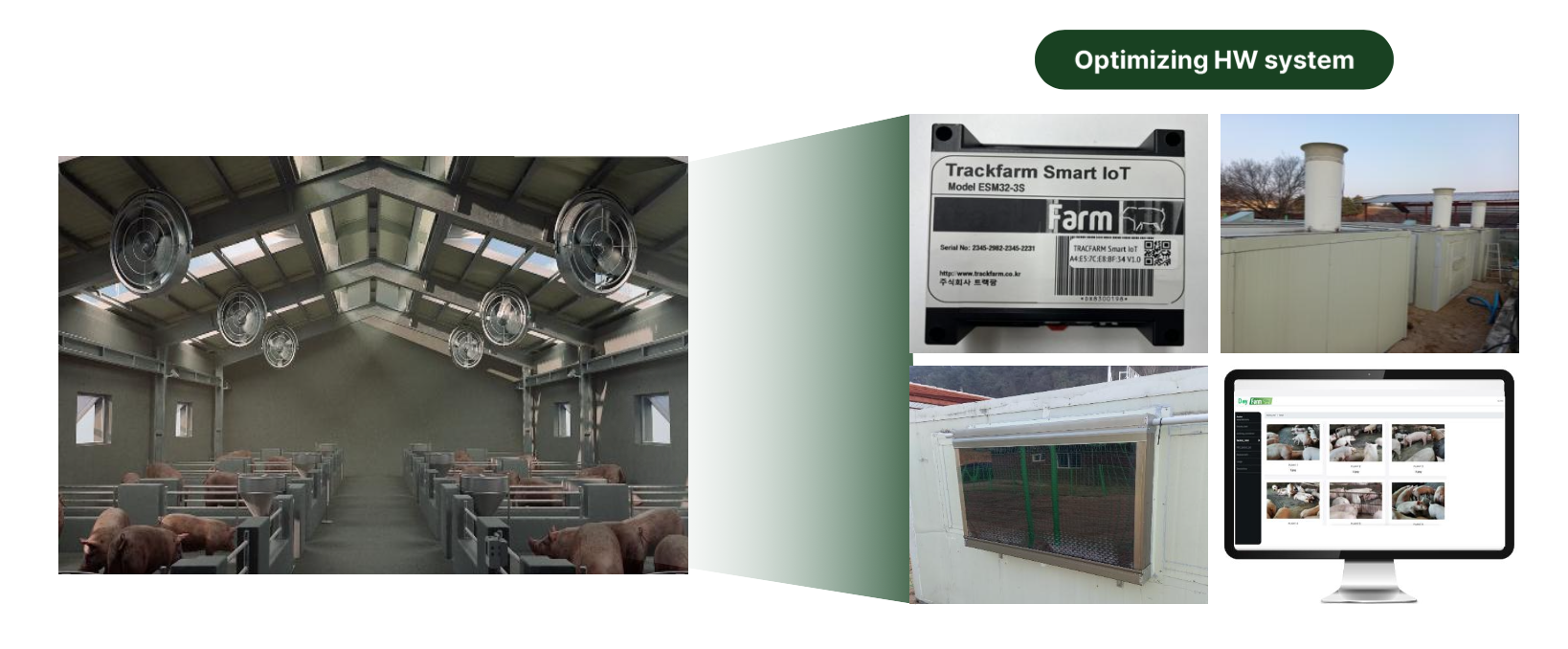

B. The Automated Environmental Control Engine (Hardware)

The hardware component ensures the physical environment is always at peak performance for the animals. This is critical because environmental stress is a leading cause of disease and poor growth.

- Sensor-Based Monitoring: A network of sensors continuously monitors temperature, humidity, and chemical factors (e.g., ammonia, hydrogen sulfide) within the barn.

- Dynamic Optimization: The system uses the collected data and AI models to automatically control ventilation, cooling, and opening/closing systems. This ensures the environment is precisely optimized for the pigs’ current growth stage and external weather conditions.

- Biological Factor Management: By controlling the physical and chemical environment, the system indirectly manages biological factors, reducing pathogen load and stress, which is key to lowering the mortality rate.

This automated, closed-loop system guarantees a stable, optimal environment, leading to faster growth cycles and healthier livestock.

III. Scalability and Market Potential: The Global Opportunity

Trackfarm is not limited to a single geography or farm size. Its cloud-based architecture and modular hardware design make it inherently scalable, positioning it perfectly to capture market share in diverse global markets.

A. Proven Success in Diverse Environments

The solution has demonstrated its effectiveness across vastly different operational and climatic conditions, proving its adaptability and robustness.

- Case Study 1: South Korea (Hoengseong, Gangwon-do)

- Scale: Over 2,000 pigs managed.

- Results: Significant reduction in labor and operating costs, shortened rearing cycles, and a measurable decrease in the mortality rate. This success in a high-cost, high-tech market validates the efficiency gains.

- Case Study 2: Vietnam (Dong Nai, Ho Chi Minh)

- Scale: Over 3,000 pigs managed.

- Results: The system successfully optimized the environment for high-quality rearing despite the challenging local tropical climate. This demonstrates the system’s ability to adapt its control algorithms to unique environmental variables, a crucial factor for global expansion.

This dual-market validation—proving both cost-efficiency in a developed market and environmental optimization in an emerging market—underscores Trackfarm’s global readiness.

Cloud Analytics/AI -> Optimization Engine -> Automated Hardware Control (Ventilation/Feeding), showing a closed-loop system.” />

Cloud Analytics/AI -> Optimization Engine -> Automated Hardware Control (Ventilation/Feeding), showing a closed-loop system.” />

B. Diagram Idea: The Trackfarm Value Chain Transformation

To illustrate the investment potential, consider the transformation of the traditional swine value chain:

Diagram Idea: Trackfarm’s Impact on the Swine Production Value Chain

- Input: Traditional (High Labor, High Feed Waste, Reactive Management) vs. Trackfarm (Low Labor, Precision Feeding, Proactive AI)

- Process: Traditional (Longer Rearing Cycle, High Variability, High Mortality) vs. Trackfarm (Shortened Cycle, Low Variability, Low Mortality)

- Output: Traditional (Inconsistent Quality, Lower Profit Margin) vs. Trackfarm (Consistent High Quality, Maximized Profit Margin)

This visual representation would clearly show investors where the value is created: by compressing the time-to-market and maximizing the yield and quality of the final product.

IV. Financial and Operational Metrics for Investors

The investment opportunity is underpinned by clear, quantifiable metrics that translate technological superiority into financial performance.

A. Key Performance Indicators (KPIs)

The following table highlights the operational improvements that drive the financial ROI:

| Metric | Industry Average (Traditional) | Trackfarm Performance (Case Studies) | Improvement Driver |

|---|---|---|---|

| Labor Efficiency | 1 manager per 500-1,000 pigs | 1 manager per 3,000+ pigs | AI Monitoring & Automation |

| Mortality Rate | 5% – 10% (Highly variable) | Significantly Reduced (Data-driven health management) | Proactive Disease Detection |

| Rearing Cycle | 180 – 200 days | Shortened Cycle (Optimized growth environment) | Automated Environmental Control |

| Management Cost | High (Labor, inconsistent feed use) | Substantially Lowered | 99% AI Labor Replacement |

The ability to manage six times the number of animals per employee is a powerful lever for margin expansion, especially in regions with rising labor costs.

B. The Recurring Revenue Model and Expansion Strategy

Trackfarm’s business model is inherently attractive to investors:

- Hardware Installation (Initial CAPEX): Revenue from the sale and installation of the sensor and automation hardware.

- Software Subscription (Recurring MRR/ARR): High-margin, recurring revenue from the AI monitoring, data analytics, and cloud services. This provides predictable cash flow and a high customer lifetime value (CLV).

- Data Monetization (Future Potential): The vast, high-quality data collected on animal growth, environmental factors, and optimal management protocols can be anonymized and leveraged for future services, such as precision feed formulation or insurance risk assessment.

The expansion strategy is focused on leveraging the proven case studies to penetrate new markets in Asia and eventually the Americas and Europe, targeting large-scale commercial operations that stand to gain the most from the efficiency boost.

V. Competitive Advantage and Moat

Trackfarm’s competitive edge is not merely in its components but in the seamless integration of its AI and hardware, creating a data feedback loop that continuously improves the system’s performance.

- Data Moat: Every farm deployed adds to the proprietary dataset, making the AI models more accurate and the system’s performance gap with competitors wider over time. The system learns from diverse global conditions, making it more robust than localized solutions.

- Labor Replacement: The 99% labor replacement claim is a critical differentiator. Most competitors offer “assistance” tools; Trackfarm offers “automation,” solving the most acute problem in the industry.

- Holistic Optimization: By controlling both the biological (through AI monitoring) and physical (through automated environment) factors, Trackfarm offers a truly holistic optimization that single-point solutions (e.g., just a smart feeder) cannot match.

VI. Conclusion: Investing in the Future of Protein Production

Trackfarm represents a rare opportunity to invest in a proven, scalable technology that addresses a fundamental global need: efficient and sustainable protein production. The solution’s ability to dramatically reduce operational costs, lower mortality, and optimize time-to-market provides a clear and compelling ROI for farm operators, which in turn translates into strong, predictable returns for investors.

The future of livestock farming is intelligent, automated, and data-driven. Trackfarm is not just participating in this future; it is building it. We invite investors to join us in capitalizing on the massive market potential of this transformative Ag-Tech solution.